In today’s technology-driven world, maintaining the reliability and efficiency of electronic systems is essential. One of the most effective ways to ensure this reliability is through advanced EMI Electromagnetic Interference shielding materials. These specialized materials provide powerful protection, preserving signal integrity and extending the life of modern devices across numerous industries.

Why EMI Shielding Matters

Electromagnetic interference can cause signal disruptions, reduced performance, and even complete system failure. To combat these issues, EMI shielding materials act as a barrier that blocks unwanted electromagnetic waves, ensuring smooth device functionality. Selecting the right emi shielding materials ensures proper signal integrity in electronic circuits.

Key advantages of EMI shielding include:

- Prevents electronic noise and interference.

- Maintains optimal device performance.

- Ensures safety and reliability in high-frequency environments.

- Protects sensitive circuits and data transmission channels.

Types of Advanced EMI Shielding Materials

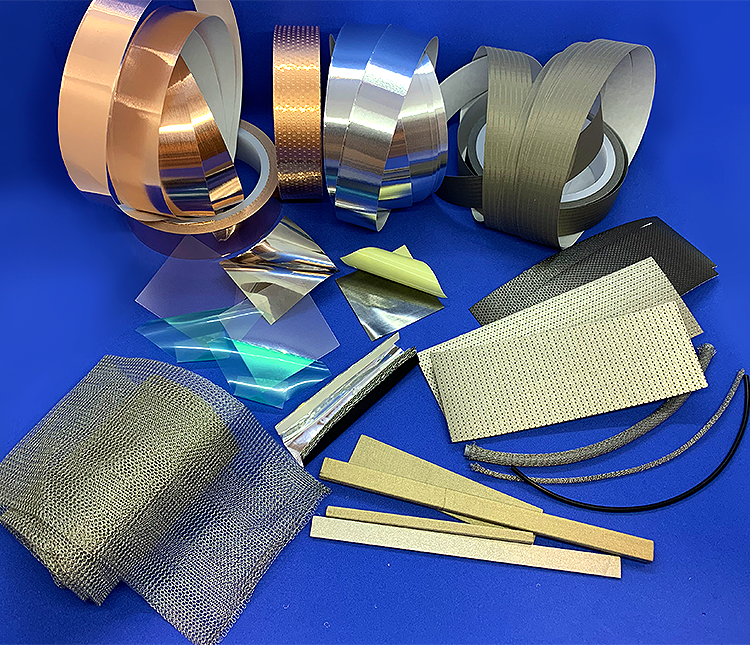

Modern EMI shielding technology has evolved to include a wide range of high-performance materials designed to meet diverse application needs.

- Conductive Polymers

- Lightweight and flexible, making them suitable for compact electronic designs.

- Offer excellent conductivity and are ideal for wearable or portable devices.

- Metal Foils and Meshes

- Commonly used for enclosures and cables.

- Deliver robust shielding performance and mechanical durability.

- Carbon-Based Composites

- Combine strength, conductivity, and environmental resistance.

- Provide superior EMI protection without adding excessive weight.

- Conductive Coatings and Paints

- Easily applied to surfaces for quick EMI protection.

- Perfect for prototypes and large-scale production.

The Science Behind EMI Shielding Efficiency

EMI shielding materials work by reflecting or absorbing electromagnetic waves. Conductive materials redirect unwanted signals, while absorptive materials neutralize interference energy. The combination of these two mechanisms ensures comprehensive protection for sensitive electronics. Testing ensures that emi shielding meets industry standards for electromagnetic compatibility.

Performance factors that determine shielding quality include:

- Electrical conductivity

- Material thickness

- Frequency range of interference

- Proper grounding and enclosure design

Benefits That Enhance Device Longevity

The use of advanced EMI shielding materials leads to long-term benefits for both manufacturers and users.

Major benefits include:

- Improved durability: Devices are less prone to wear and performance degradation.

- Enhanced reliability: Components remain stable even under heavy electromagnetic exposure.

- Increased productivity: Fewer interruptions and malfunctions improve efficiency.

- Eco-friendly solutions: Modern shielding materials are often recyclable and energy-efficient.

Future of EMI Shielding Innovation

As electronics continue to advance in speed, sensitivity, and compactness, EMI shielding materials will evolve to meet new challenges. Emerging nanomaterials, hybrid composites, and flexible coatings are expected to redefine how electromagnetic protection is achieved.

With continuous research and innovation, advanced EMI shielding materials promise to provide even greater protection, efficiency, and sustainability ensuring that every device performs at its peak in a connected, high-frequency world.

In conclusion, EMI shielding is more than just a technical requirement it is a foundation for reliability and performance. By integrating advanced shielding materials, industries can experience ultimate protection, improved functionality, and lasting peace of mind in every electronic application.